Friendly Operation Instant Vision Measuring System With Long

Working Distance

1. Application

It is widely used in quick batch measurement of precision screws,

precision springs, gears, cell phone case, cell phone glass,

precision metal parts and other parts in small size.

2. Specification:

Model | iVS-160 |

Code# | 500-160 |

Lens | 0.088X Double Telecentric Lens |

Working Distance | 390mm |

Wide Field | Ø160mm |

Measurement Accuracy | ±7um |

Repeatability Accuracy | ±5um |

Camera | 2/3’’ 5 million pixel B/W camera (Ethernet) |

Illumination | Digital controls, automatic memory |

Telecentric Green LED Contour illumination |

Ring White LED illumination |

PC System | DELL (I5 Intel processors) |

Monitors | Built-in 10.4 inch LCD Monitor(1920*1080) |

External 21.5 inch LCD Monitor(1920*1080) |

Measuring Software | iMeasuring 2.0 |

Measuring Amount | Max.99 |

Test Time | <5S (Less than 100 tests) |

Output data | Test data, reports, determine the results (OK, NG, WAIT), etc |

Function | 2D measurements: points, lines, circles, arcs, angles, distance,

oval, O-rings, Groove, rectangle, parallelism |

Auxiliary Function | Intersection, parallel, perpendicular, tangent, bisection. |

Geometric Tolerances | Dimension tolerances and position tolerances, tolerances of form

and position (Point position concentricity, straightness,

parallelism, roundness, straightness, profile, etc) |

Measurement Mode | Manual / Automation |

SPC Data Management and Control | √ |

CAD Data Input / Output | √ |

Power Supply | AC100~240V,50~60Hz |

3. Features

* High accuracy and excellent repeatability

* Friendly operation

* Efficient batch measurement

* Quality Control and Statistical Process Control(SPC)

3.1 Perfect Accuracy

Recover the original dimension with high accuracy

Double telecentric lens and high depth of field, allow height

difference in sample, section with slope or curvature and other

difficult measuring elements. And low distortion without having to

worry about sample placement and blurred focus, and recover the

original dimension with high accuracy.

3.1.2 Low distortion lens, clear edge image, no distortion,

eliminate measuring error.

3.1.3 Software with sub-pixel (Sub Pixel), least-square method

regression algorithm and high video compensation to ensure

accuracy.

Sub Pixel edge detecting image processing algorithm makes

pixel-division smaller, closer to the actual edge.

The least-square method automatically removes burrs and outliers,

ensure the least influence on feature location.

3.2 Efficient Batch Measurement

Takes only 2~5 seconds to measure dozens of position, 99

measurements can be conducted at a time within the measuring

range,it significantly shortens the measurment time and improve

measurement efficiency.

3.3 Entire image

No need to move working stage, efficient and high accuracy

3.3.1.Traditional measuring instruments have narrow field of

vision, can only test one position at a time, and it requires to

move working stage and position specimen before measuring.

3.3.2Traditional measuring instruments repeatable steps and more

time-consuming and complex to operate.

3.3.3 Traditional measuring instruments need to consider the

accuracy of supporting hardware, such as, linear scales, working

stage mounting accuracy, etc.

It can image overall within the maximum range of the measuring

field, measurement of multiple sizes can be finished at once,

greatly improve efficiency, save time and cost of production.

Meanwhile, it meets customers’ idea "without mosaic, overall

image".

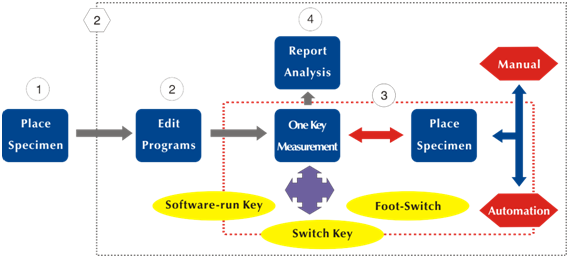

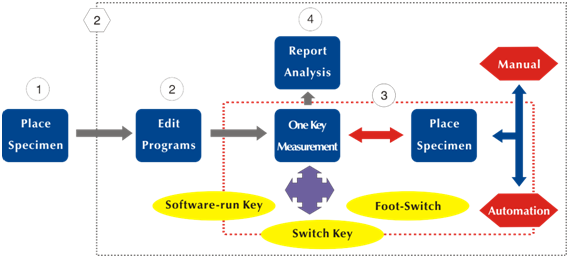

3.4 Friendly Operation, Low Costs.

High efficiency, save labor cost, eliminate operator error.

3.4.1 No fixture, location, correction, focus, lighting, running

control requirements, automatically measure within the maximum

range of the measuring field, greatly improve efficiency.

3.4.2 Anyone can operate, general workers can meet the

requirements, high efficiency, save labor cost.

For example | Other measuring instruments | Instant Vision Measuring System |

Save training costs | It takes a long time to learn the instrument operation | One key operation, anyone can operate |

Worried about losing skilled operators, resulting in "disconnect" |

Lower utility costs | Limited to skilled operators, high salary requirements (1000 USD/month) | Anyone can operate, general workers can meet the requirements (500

USD / month) |

Save test efficiency costs | Equipped with 5~10 machines in one production workshop, each

equipped with at least one or two skilled operators | Instant Vision Measuring System, one general worker |

3.5 Effectively Eliminate Operator Error

Avoid operated method, specimen placing, measuring sequence,

eliminate the operator error efficiently.

Human error elements | Other measuring instruments | Instant Vision Measuring System (Eliminate Human Error) |

Measuring Method | The operator is not familiar with the software and the machine | Memory and storage of measurement method, point position and test

direction, auto running, eliminate operator error efficiently |

Operators emotion changes will cause accuracy and stability

deviation | Automatic & Mechanization, eliminate operator error |

Short working distance and depth of field, repeatedly focusing will

cause misjudgment and mechanical tolerance | High DOF double telecentric lens, long working distance, allow

height difference, no need to repeat focusing |

Different operators, different habits and focus clearness, point

selection, illumination intensity, different results | Automatically memorize illumination, measuring mode, point

selection mode. |

Specimen Placing | Different positions and directions | Without fixture, and place randomly |

Fixture shift, point location will cause coordinate origin error | Automatic location and direction adjustment and take accurate

measurement |

Point position and measured elements are out of sequence | Automatic & Mechanization |

3.6 Simple Application

3.6.1. Automatically record and output the measured values to WORD,

EXCEL, TXT documents and SPC statistics and analysis which makes it

easy for the test data application.

3.6.2 It can set tolerances, when measurement exceeds the

tolerance, it has automatic alarm and automatically SPC statistics

and analysis and output the reports.

3.7 Support Reverse Engineering:

Imported DXF files by software can be measured, graph and data can

also be exported from the software for DXF files for other

applications.